Current problem

State of knowledge and technology

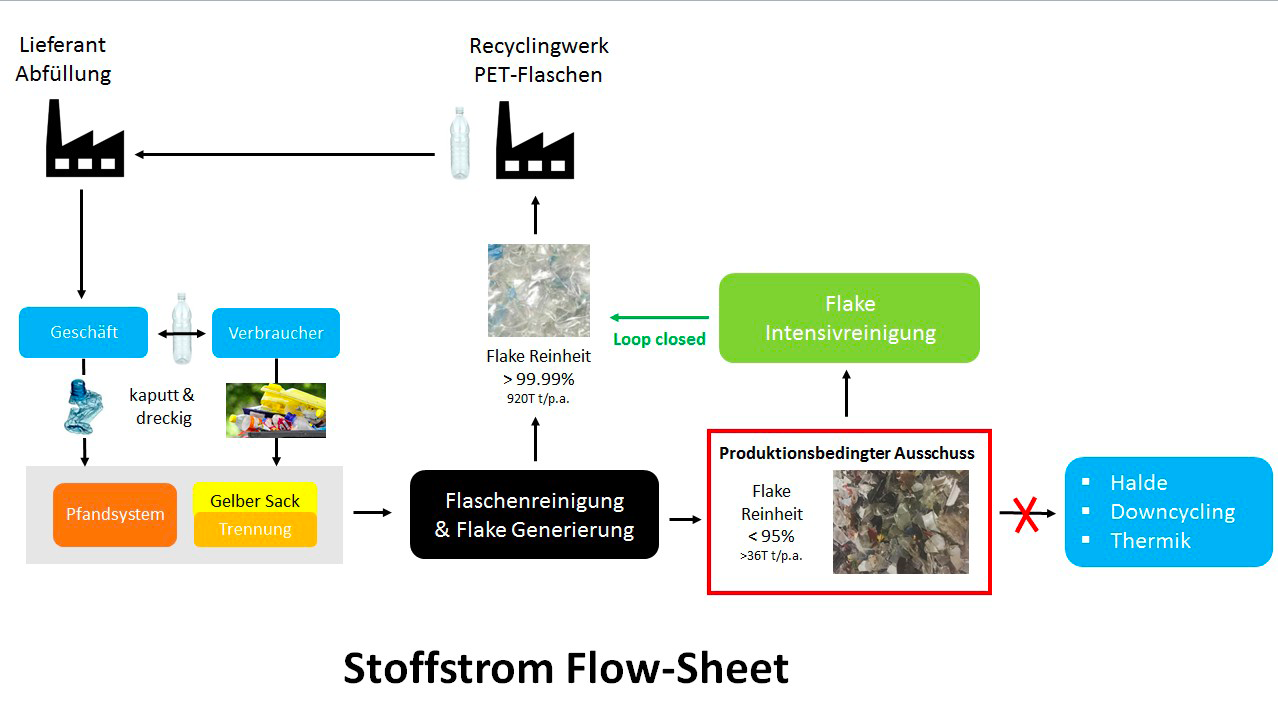

In Germany, around 1 million tons of polyethylene terephthalate (PET) plastic waste are produced every year, mainly from food packaging and beverage bottles in particular.

The problem here is that there is still no fully closed-loop recycling system for food packaging: The plastic waste that has already been pre-sorted by the domestic waste separation system and the deposit system, afterwards sorted in sorting plants according to parameters such as size, weight and material type and grinded into "flakes". This is followed by various washing and cleaning steps as well as colour and polymer sorting.

The result is a raw material that can be reprocessed in the plastics industry.

However, today's sorting plants produce a consistent reject, with an unsufficient quality-level for the production of packaging and preforms.

For food standards, the sorting purity must be at least 99.99%. As a result, these volume flows, estimated to be >40,000 tons per year just in Germany, which are approx. 4% of the total PET consumption, cannot be reused for food packaging in a closed circular economy.

Just a few years ago, the resulting waste was sold to Asia as low-grade PET mixed fractions for downcycling. This sales market has largely disappeared. The low-grade by-products now is directed into downcycling or are even sent to waste incineration plants/refuse-derived fuel (RDF) power plants for energy recovery and thus contribute to environmental pollution.